COMPONENT MAINTENANCE

COMAF is certified by ANAC and EASA for maintenance of mechanical, electrical, hydraulic, electronic, instrument, propeller and structural components with more than 20.000 different Part Numbers applied to commercial, executive and military aviation, for both fixed and rotary wings.

We are also one-stop shop for any necessity in maintenance of components, having a great experience in management of repairs executed in outsourced workshops always seeking the best price and quality for our clients.

Our workshops are divided as follows:

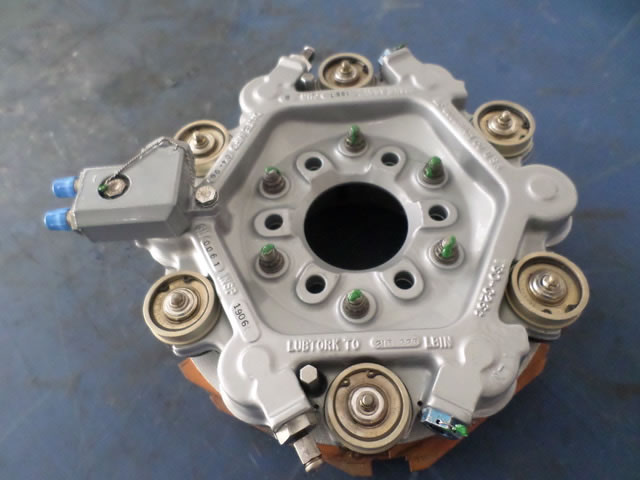

Propeller System

Carbon Propellers

Actuators

Hubs

Spinners

Bulkheads

Transfer Tubes

Aircrafts: EMB-120, ATR-42/72, CASA-295

Wheels and Brakes

Metal brakes.

Carbon brakes.

Wheels in general.

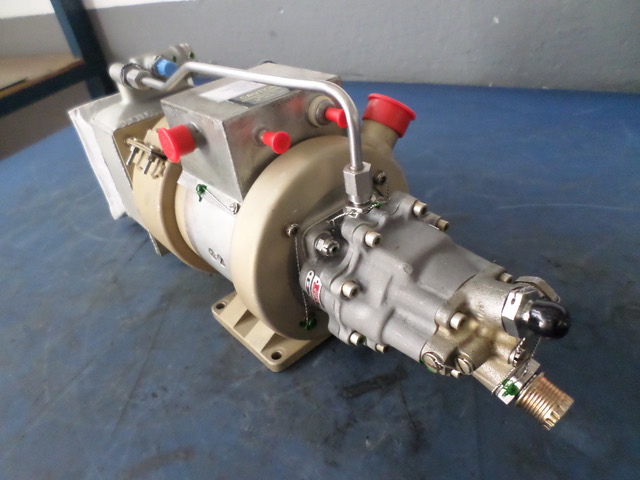

Hydraulics

Landing Gears

Hydraulic Pumps

Hydraulic Actuators

Propeller Control Units (PCU’s)

Propeller and Overspeed Governers

Propeller Brake

Hydraulic Valves

Transmissions

Electrical and Pneumatic

Starter Generators.

AC & DC Generators.

Electric motors.

Electric pumps.

Electric and pneumatic valves.

Air Cycle Machines (ACMs).

Electric and pneumatic actuators.

Electronics

Generator Control Units (GCUs).

Electronic Fans.

Sensors.

Electronic Batteries.

Navigation and Emergency Lights.

Electronic components in general.

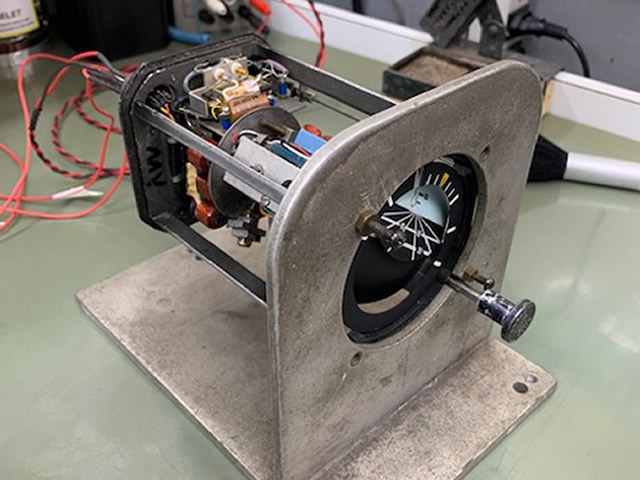

Instruments

Altimeters.

Speed indicators (air and ground).

Gyroscopes.

Indicators in general.

Outflow valves.

Batteries

Nickel-Cadmium Batteries.

Lead-acid batteries.

Structural Repairs

Complete repair in Sikorsky S76 cell.

Repairs in metallic, composite and mixed material.

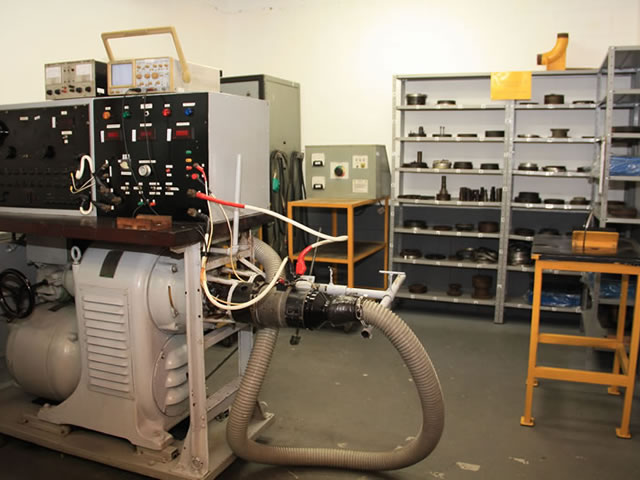

Tests

The dedicated sector for conducting operational tests.

Hybrid and dedicated workbenches.

Capacity for tests with air, fuel, conventional hydraulic oil and skydrol

Capacity for pneumatic tests.

Technical personnel unique to the sector.

NON-DESTRUCTIVE TESTS

Penetrating liquid.

Magnetic particles.

Parasitic chains.

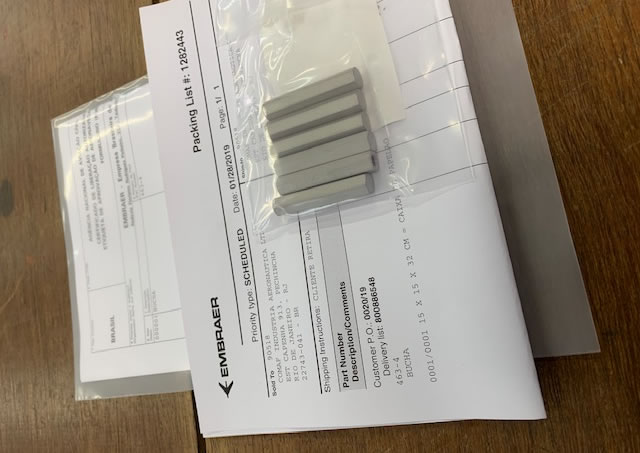

RECEPTION / EXPEDITION